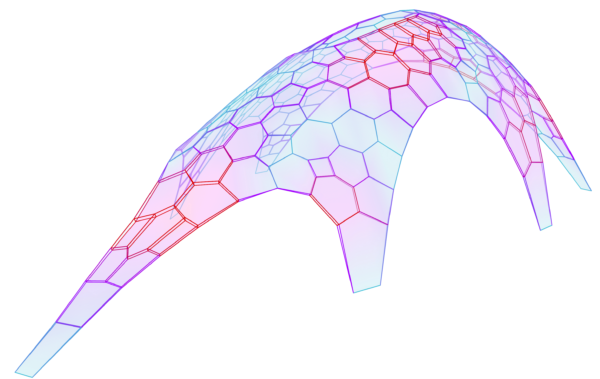

A renewed interest in stereotomy, narrowly entwined with digital technologies, has allowed for the recovery and proposal of new techniques and expressions in this building approach. A new classification scheme for stereotomy research allows for the framing of various aspects related to this discipline, including a newly developed fabrication system specially tailored for the wedge-shaped voussoirs. This fabrication system is based in a reusable mould which may assume an infinite number of geometries, avoiding the wasteful discarding of material found in subtractive strategies. The usage of a mould also allows for more sustainable materials to be employed, catering to current challenges. The strategies subject for demonstration in this project rely on various bottom-up approaches, which involve particle physic simulations such as a hanging model to compute an optimal stereo-funicular shape, or spring mechanisms to find optimal coplanar solutions. The proposed mechanisms work in a parametric algorithmically environment, able to handle dozens of uniquely different voussoirs at the same time. Together with the automatic translation to fabrication data, the proposed shape complexity would hardly be built with classic tools. The Tamandua Vault project has the purpose of exemplifying the possibilities of an updated stereotomy, while its design demonstrates current strategies that may be employed in the resolution of complex geometrical problems and bespoke fabrication of construction components for stereotomy.

You can read the full paper here: http://papers.cumincad.org/cgi-bin/works/paper/ecaade2020_115